A History of Expertise and Innovation

RJ Lee Group has assessed environmental issues since the early 1980s when our Energy Technology Consultants (ETC) pioneered the recognition of specific air quality patterns. We developed a cutting-edge technique for identifying, measuring, and characterizing particles in the air using computer-controlled scanning electron microscopy (CCSEM).

RJ Lee Group has worked with clients in various industries, including the U.S. Environmental Protection Agency (EPA), to assess and provide solutions for environmental factors that could affect our health. Our services have grown over the years, from setting controls for unbound nanoparticles (UNP) to designing and building test chambers to simulate specific environmental conditions.

Today we offer our expertise for our clients’ environmental and compliance concerns and perform rigorous assessment and management of potential environmental risks.

CONSULTING AREAS

Quality Assurance

As global markets expand and competition intensifies, the need for rigorous quality assurance testing and regulatory compliance has never been greater. RJ Lee Group, your trusted partner in quality assurance, empowers businesses to navigate this complex landscape with confidence.

Manufacturers, regulatory bodies, trade groups, contractors, designers, and sales organizations increasingly turn to RJ Lee Group's third-party quality assurance testing to safeguard product integrity and meet stringent requirements. Our team of experts performs meticulous quality assurance testing throughout every stage of the product life cycle, from concept to completion. We scientifically scrutinize the manufacturing processes with the goal of identifying potential issues before they can adversely affect production and recommend corrective actions when unexpected problems occur.

RJ Lee Group's quality assurance services have aided a diverse portfolio of clients in both the private and public sectors. Our expertise ensures:

- Improved Product and Service Quality: Your products and services will consistently meet or exceed industry standards.

- Regulatory Compliance: We help you navigate complex regulatory landscapes and maintain compliance, avoiding costly setbacks.

- Reduced Legal Risks: Our thorough quality assurance minimizes the likelihood of legal entanglements, safeguarding your reputation.

Quality Control

We partner with our clients to achieve continuous improvement across the product life cycle and help them gain and preserve a competitive edge in a rapidly changing regulatory landscape. Our experts analyze the manufacturing process and products to detect problems, mitigate them, and

prevent their reoccurrence.

Failure Analysis

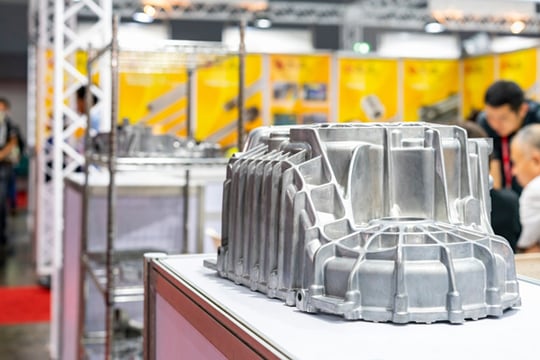

Equipped with a comprehensive materials characterization laboratory, our team of highly skilled scientists collaborates with clients from various industrial sectors to identify the underlying causes of failures at every stage of production, development, and operational products.

RJ Lee Group is also trusted as a third-party laboratory, providing unbiased evaluations for warranty claims. Our clients deeply appreciate the credibility of our data and the invaluable insights offered by our scientists, all delivered within their desired timeframe to meet their business requirements.

Complex Regulations

We keep you compliant

As the world evolves with new materials, practices, and product integrations, the complexities of navigating this ever-changing landscape are growing more and more demanding.

RJ Lee group can assist in navigating your products through rigorous standards via both interpretation of legacy and newly adopted regulations and testing for compliances.

Expert Spotlight

Keith Wagner

Senior Materials Scientist

Keith has over 30 years of experience and is currently a Senior Materials Scientist with supervisory and technical responsibilities focused on industrial problem solving, forensic materials investigations and failure analysis for commercial, legal and governmental clientele. He has conducted materials evaluations on all classes of materials. He has also published and presented on materials processing and failure analysis in the areas of metallic alloy systems, concrete and structural materials, nanotechnology, CO2 sequestration, particle and residual materials analysis, corrosion, wear and applications of various materials characterization techniques.

Case study

How AeroTech Secured Its Future

When AeroTech Industries faced recurring defects in a crucial aircraft component, they were at risk of losing multi-million dollar contracts and jeopardizing the jobs of hundreds of employees. They enlisted the help of RJ Lee Group, who quickly deployed a team of technical experts. Through state-of-the-art forensic analysis, RJ Lee Group identified and rectified the root cause—a flaw in the casting process—eliminating the defect and preserving AeroTech's contracts.

Discuss Your Quality Assurance Testing Needs with an Expert

In a world full of choices, make your product stand out from the rest and improve product quality with RJ Lee Group’s quality assurance testing. Schedule a call with an expert today to discuss your quality assurance needs.